There comes a point when you need quality data to lift production management and operational efficiency. Most often this occurs soon after assets are brought online and the control systems are already in use.

As the requirements for the system mature, opportunities for improvement begin to surface. To justify change, good data and better information on how assets perform are the foundation to measure the expected operational uplift. If an improvement in production can be realised by having superior information about asset performance, it is easy to calculate a return on investment linked to additional technology. What is less tangible than improved asset performance is the value that will inevitably be discovered as new data consumers discover patterns in operations, maintenance impacts are exposed, and other never before seen aspects of their system surface. These are the gold nuggets hidden below the surface.

Denison Gas operate two gas fields centred around two separate SCADA servers at Yellowbank and Rolleston. Bringing two SCADA systems together has obvious benefits for production management and planning, however, extending an operational control system and centralising data creates a number of benefits beyond the reach of the SCADA technologies.

SCADA systems have long been challenged by providing the functions offered by Process Historians. As the SCADA system gathers data from many field devices, the information is gathered in real time as change occurs. The real time systems detect alarm conditions, store data, and alert operators, and operators also control devices remotely. Within SCADA, real time data is stored in proprietary databases, files or relational databases. There are a number of challenges with this basic functional description, however, the key reasons for complementing a control system with a process historian is as follows:

The process historian provides isolation between the control system and the corporate systems. SCADA systems are poor data providers and the number of clients accessing SCADA must be considered carefully when architecting the system. A Process Historian is complementary to SCADA. A single consolidated data stream from SCADA to the Process Historian provides a more efficient access method and delivers the very same data sets but with new context. Metadata can be created for the data stored and the Process Historian can also source data from non-SCADA sources. Process Historians provide many more clients than SCADA can normally provide both technically and cost effectively. The Process Historian can be positioned on a different network segment to SCADA whether it is in the cloud or on premise (or a mix of both). Either way, this single connection from Process Historian to SCADA can easily be managed with rigor by network administrators. This is a Cyber Security specialists dream come true when trying to isolate Control Systems from their Corporate users.

High volume data users require vast datasets and this sometimes includes years of data as seasonal and production cycle evaluations are conducted. Heavy data access to SCADA systems diminishes performance of SCADA and compromises operational integrity. The larger a system is, the more significant the impact. Because the Process Historian acquires the data from SCADA at the same overall rate that SCADA acquires it from field devices, the Process Historian presents virtually no load on the SCADA Servers. This is good news for businesses who have plans to expand their SCADA. In fact, the right process Historians can gather data from dozens of SCADA systems creating an enterprise view of how all of the assets are performing, not just for a short period of time like SCADA, but often over the entire lifecycle of the assets.

Denison Gas has chosen the Process Historian pathway early in the lifecycle of their system. This gives the SCADA Systems room to breathe. As the SCADA systems scale up, there is no threat that corporate users, planners, and any other data consumers can ever impact the operation of the control systems. As the organisation grows and more users want access to the data, there are no limitations imposed by the SCADA system have only a few clients directly accessing it, and no limitations imposed by the choice of Process Historian technology.

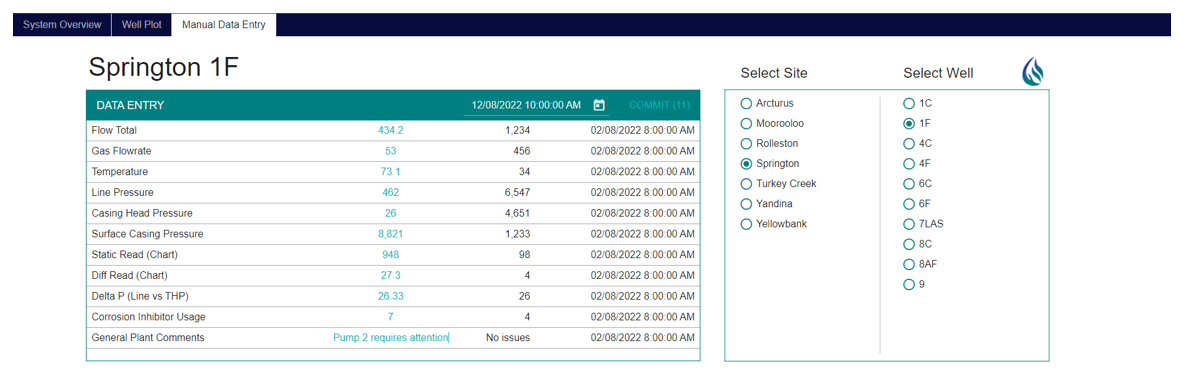

The Denison Gas Process Historian natively supports time series data. This functionally supersedes that of any relation database. Because the SCADA also supports time series data, the value sampled from instruments in the field is captured with the exact time the value is measured and the value and time stamp remains attached as it traverses the system. This means, even if the data samples arrive a little late due to network interruptions, all of the system data is ultimately synchronized. A snap shot report using the Process Historian will produce a valuable view into the system at any point in time. This millisecond resolution is as accurate as the calibration accuracy of each of the instruments. The Denison Gas SCADA system does not condition or truncate the data as do many SCADA systems. The raw data remains intact. The Process Historian maintains the data integrity serving up rich data to the business. The client application is also configured to allow easy data entry for operators and process engineers.The Process Historian is the gateway to operational excellence.

At a fraction of the cost of traditional Enterprise systems, Denison Gas’s Geo SCADA with the addition of Canary Labs Process Historian provides the foundation for elevated production performance.

For more information on the Process Historian technology used at Denison Gas, chat with Parasyn or go to: Canary Labs