Queensland Rail operates and maintains 6,600 km of track in South East Queensland and Regional areas. It operates over 8,000 services each week and relies on Electric Power to operate Electric Trains (Rolling Stock). The Traction Power SCADA System is used by Operators to manage the grid safely and in turn, indirectly maintain the safety of rolling stock and passengers. The Traction Power SCADA System has been in service for nearly 2 decades. In 2021 Parasyn was appointed as QRs Owner’s Engineer to support the upgrade/replacement of the aging Traction Power SCADA System.

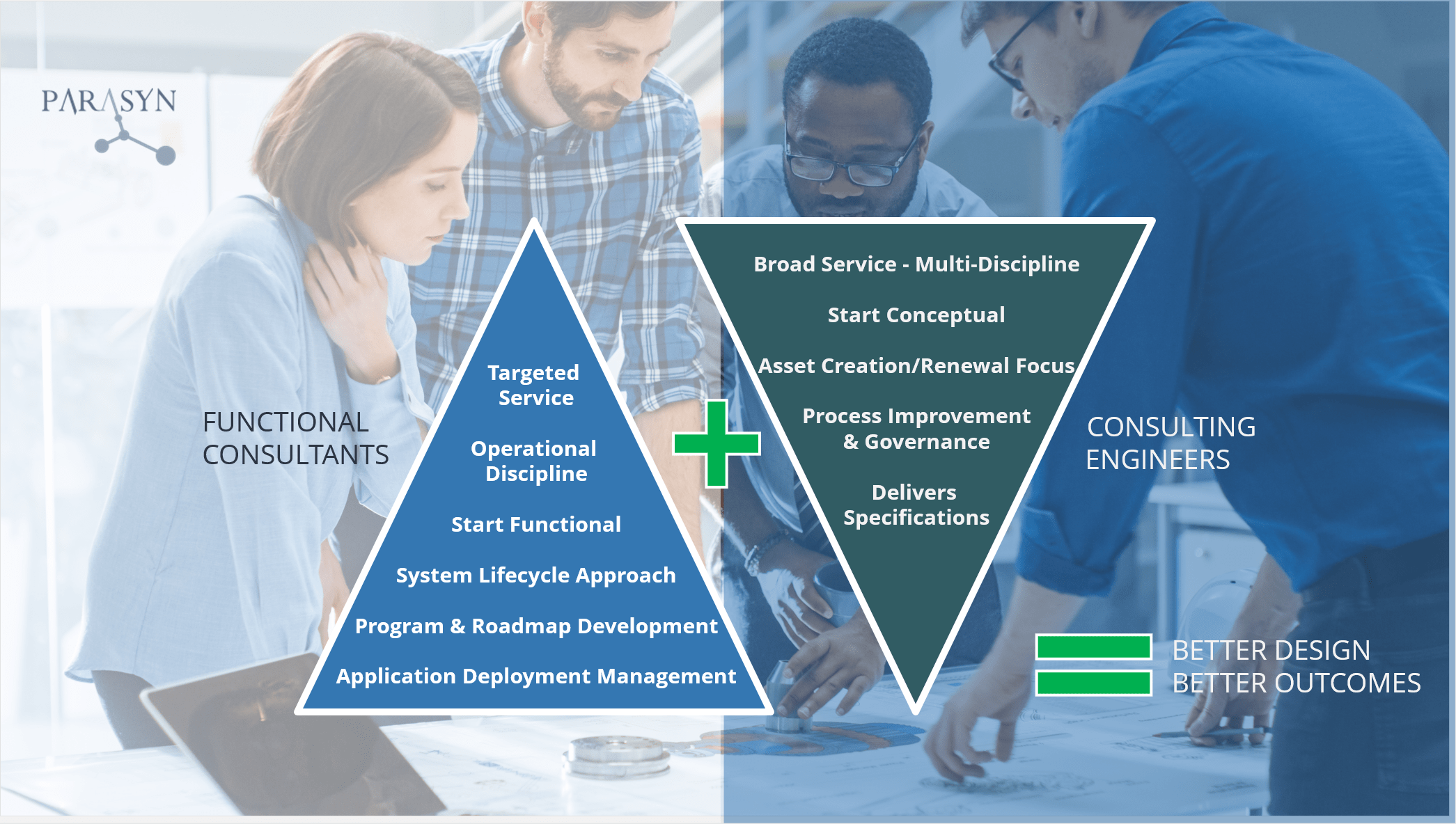

Owners’ Engineers are usually “third party” consultants overseeing or endorsing or providing critical outcomes throughout a project life cycle. Functional activities often include Project Evaluation, Feasibility, Vendor Selection and Assessments, Staging, Technology Assessments, Concept Design, Procurement and Tendering, Type Approval and Design Assessments.

Requirements are not all technical

The gap between client and customer expectations is especially challenging for Technology based projects. Good requirements which identify the process of implementation, the definition of deliverables, and of course technical specifications aim to reduce project and lifecycle risk while meeting and exceeding business and technical needs. Functional Consultants like Parasyn have the added advantage of having hands on experience, delivering “like specifications” previously. The lifecycle goals which are usually less obvious or important to the supplier and vendors are critical to the Principal especially for Critical Infrastructure like Passenger Railways.

Detailed Requirements are a good guide for suppliers to know what to expect, or not. High level motherhood statements and generic reference to standards with basic outcomes leave the Principal exposed to a plethora of methods and complexities which generally leads to commercial exposure and significant risk to meeting the organisations goals. At the planning stage, the goal is to have both parties to transparently communicate their real position and develop the execution plan based on a feasible design.

Extensive stakeholder engagement

Stakeholder engagement is a common method to validate assumptions and expose gaps in the requirements. It is also an opportunity for parties to develop a project group focussed on success and to better understand the business needs. The project group must develop a common sense approach to two-way accountability and a no nonsense sharing of all types of risk. Any withholding of information to increase commercial leverage diminishes good intentions and trust which always results in an adversarial project culture. Suppliers are acutely aware of where the delivery risk lies, and the Principal is acutely aware of operational and other risks less concerning to the supplier. The roles are different, and the Owners Engineer is key to blending expectations, process, and technical outcomes.

Strategic & Technical Advisor

As a strategic and technical advisor, Parasyn has the responsibility to provide sound technical advice. This advice may be architectural, design, methodology, and even commercial. This advice takes on strategic value when other aspects like lifecycle and impact assessments are factored in. As projects mature and the impact of technical changes become clear, risk assessments, human factors, and design acceptance create a solid platform for change management to occur.

Change Management Development

The Change Management Plan is unique to each project. There is no one-fits-all template that will ever satisfy the organisation need, therefore it is developed on a per project basis, a fundamental change to a system, or a new and relevant asset creation event.

At QR, the Safety Change Management Plan (SCMP) guides the analysis of how the business must treat its obligations to regulatory authorities and all stakeholders. The SCMP is the gateway between Technical, Operations and the Business and uses information transfer, education and training, communications, and impact assessment to validate that the technical transition plans are suitable for use. Never to be underestimated, the technical implementation plans are not complete until change management plans are cemented. This is the business’s quality and safety gate not to be trivialised.

Systems Engineering Management Practice (SEMP)

Systems Engineering Management is distinguished from general project management by its focus on the technical and engineering activities of a project. Systems Engineering is an essential component of the project’s management structure. It ensures the method of doing engineering is suitable to uncover and manage technical and other risk. The process itself is relied upon and not a function to be fabricated on a per project basis.

When used, the SEMP focuses on the technical plan of the project and the systems engineering processes to be used to produce artefacts that are used for verification of requirements, validation of system performance, and fulfilling all approved Requirements. Its purpose is to detail out those engineering tasks and to provide records of the processes to be used. Processes include design reviews, development methodologies, user acceptance planning, human factors engineering, change management, knowledge transfer, configuration management, just to name a few that are not always addressed adequately.

Owners Engineer Responsibilities

As a principal consultant working with QR, Parasyn’ s direct duty is to QR, however, this is extended to a wider community of engineering compliance including legal and ethical behaviour in all circumstances.

Parasyn also works in the wider Consultant Community as Functional Consultants who support other Principal Consultants by focusing on specific domains that complement a wider scope than Parasyn’ s remit.